Piping for two large identical reciprocating compressors, side by side, had very different vibration responses. One system had significantly larger vibrations and the concern was that the pulsation dampeners on the one system were not functioning properly. Inspections of the pulsation dampeners would require a system shutdown and an expensive internal inspection. A method to determine what was causing this differing vibration response while the system was still operating was needed.

Situation

Identical Setups with Very Different Responses

![]()

![]()

![]()

![]()

Engineering Specialties Used

Vibration

Instrumentation

High Hazard Area Field Work

Solution

Our In-House Vibration Instrumentation Was Key

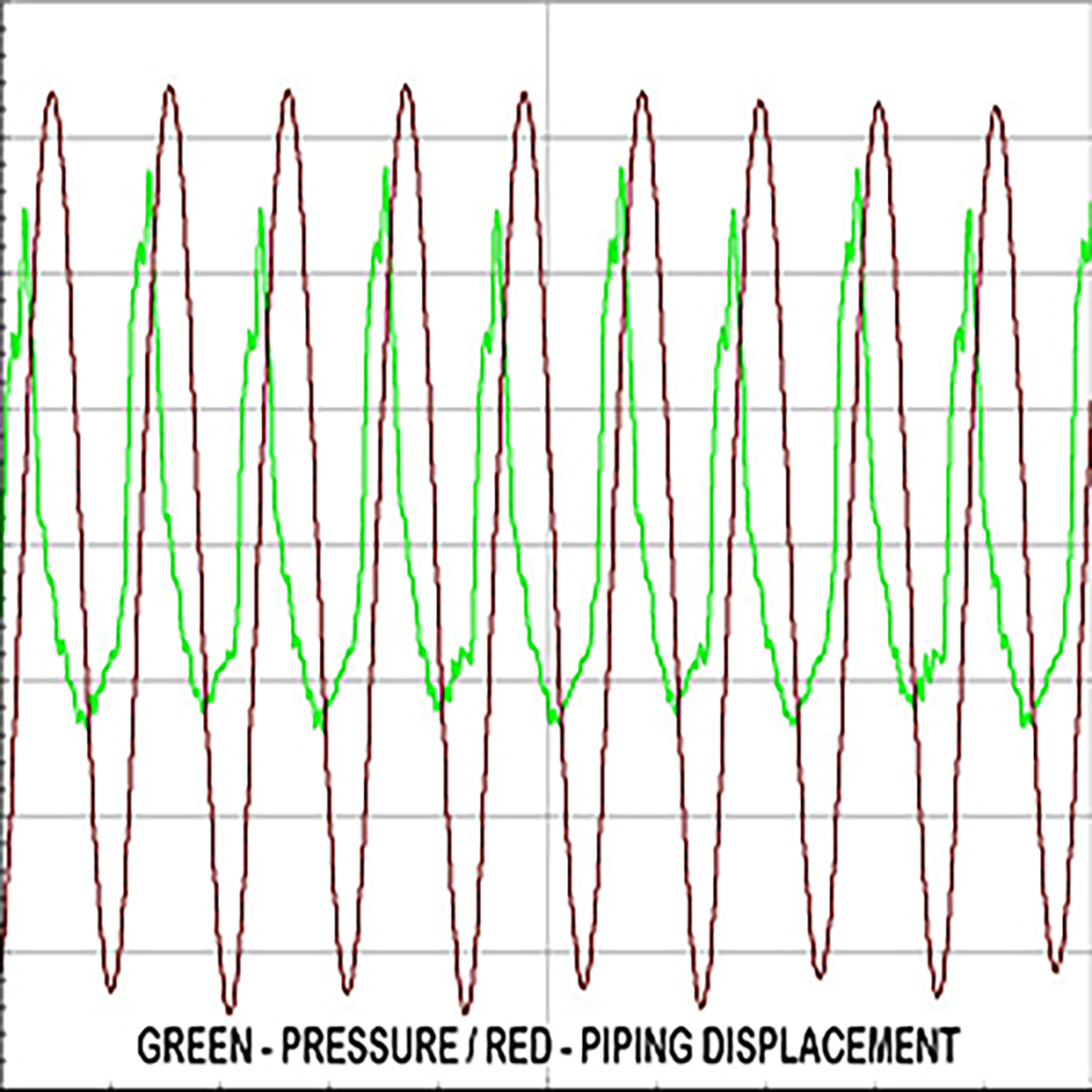

We utilize vibration instrumentation suitable for high hazard environments. All vibration equipment components are calibrated regularly per the manufacturer’s requirements. Piping pressure and displacement measurements were obtained at the high vibration locations on both compressor systems. The measurements showed similar pressure pulsations (frequency and magnitude) which meant that one system was responding differently than the other. Internal parts of the pressure dampeners were not the issue. Bracing was designed and installed at selected piping locations to reduce the excessive vibration magnitudes.

Summary

Instrumentation Provided the Needed Information

Our in-house vibration equipment is utilized regularly to measure piping, structures, pressure vessels and other components to quantify frequencies and displacement magnitudes. With this information, we are able to identify the causes of observed vibrations, and then to select appropriate remediation solutions.